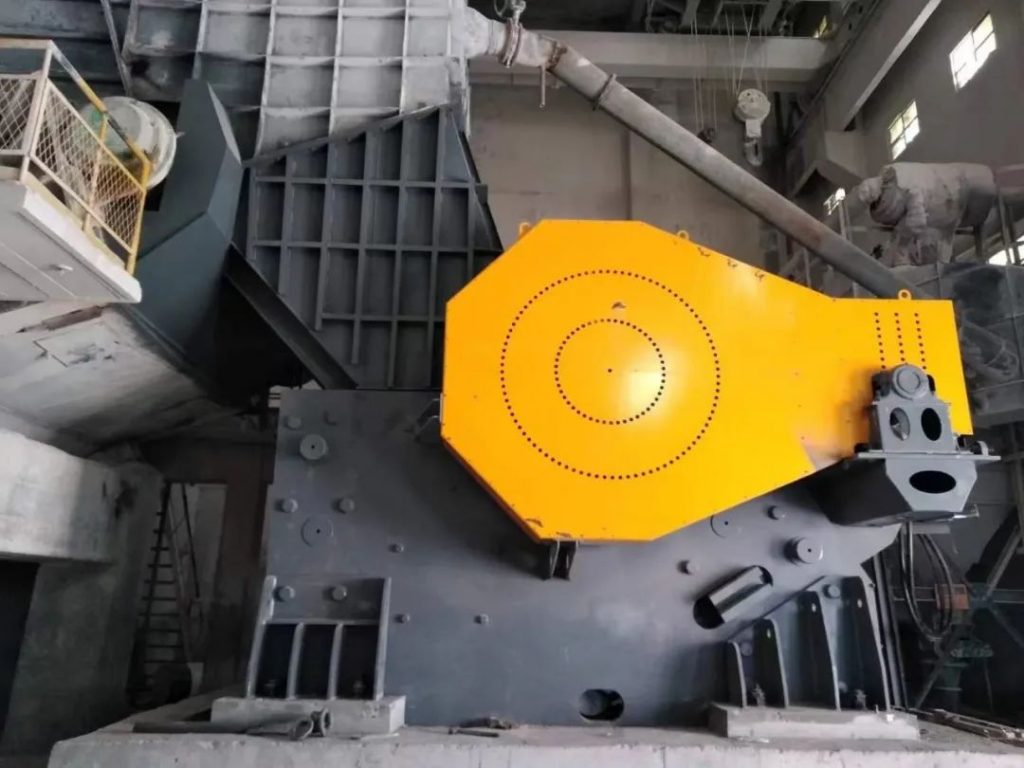

400Kw Metallurgy Feeding 460mm Cone Crusher Machine

2025-4-16

The price of jaw crusher is affected by many factors, mainly including equipment specifications, materials and processes, brand and market, configuration and function, supply and demand relationship and regional differences. The following is a specific analysis:

1、Equipment specifications

Processing capacity: The processing capacity of jaw crusher (such as feed port size, discharge port adjustment range, output) directly affects the price. The greater the processing capacity, the higher the price.

Model size: Large jaw crusher (such as PE-1000×1200) is significantly more expensive than small models (such as PE-400×600).

2、Material and process

Material selection: The material of key components such as main frame, jaw plate, eccentric shaft (such as high manganese steel, alloy steel, ordinary steel) affects durability and price. High wear-resistant materials cost more.

Manufacturing process: Precision casting, heat treatment process, welding technology, etc. improve equipment performance, but also increase costs.

3、Brand and market

Brand effect: Well-known brands (such as Sandvik and Metso) usually have higher prices than ordinary brands due to their advantages such as technology accumulation and after-sales service.

Market competition: In regions or periods with fierce market competition, prices may be more flexible; conversely, brand premiums may be higher.

4、Configuration and function

Additional functions: Hydraulic adjustment, automatic lubrication, intelligent monitoring and other configurations improve the convenience and safety of equipment, but will increase costs.

Customized requirements: Special working conditions (such as high-hardness materials and harsh environments) require customized designs, and prices will rise accordingly.

5、Supply and demand relationship

Market conditions: Fluctuations in the prices of raw materials (such as steel) and changes in industry demand directly affect production costs, and thus affect selling prices.

Inventory and promotion: Manufacturer inventory pressure, promotional activities, etc. may cause short-term price fluctuations.

6、Regional differences

Transportation costs: The equipment is large in size and heavy in weight, and the transportation distance and method (such as land transportation and sea transportation) affect the final price.

Regional policies: Some regions have strict environmental protection standards, and additional dust removal equipment is required, which increases costs.

7、After-sales service

Warranty period: Long-term warranty service may be included in the price.

Technical support: Value-added services such as on-site installation, commissioning, and training may affect the overall quotation.

8、Technology upgrade

Energy-saving design: New energy-saving motors, optimized transmission systems and other technologies improve energy efficiency, but the cost may be passed on to users.

Environmental protection standards: Equipment that meets the latest environmental regulations (such as low noise and low dust emissions) costs more.