400Kw Metallurgy Feeding 460mm Cone Crusher Machine

2025-3-6

As we all know, the main function of the movable cone of a cone crusher is to impact and crush the materials entering the crusher. Due to long-term continuous impact and crushing, the wear of the movable cone is inevitable. So, what are the factors that cause damage to the movable cone of a cone crusher? Let’s take a look below!

1、Material factors

Unqualified crushed materials: When the particle size or hardness of the crushed material is too large and exceeds the feeding requirements of the cone crusher, it will cause serious wear to the movable cone. Especially when there are unbreakable hard objects (such as iron blocks) in the equipment, it will not only cause the spring safety device to fail, but also cause the movable cone to deflect, so that the main shaft of the equipment cannot be in uniform contact with the eccentric sleeve, resulting in high-speed rotation of the movable cone, severe wear, and even flying cone phenomenon.

Uneven feeding: Uneven feeding will cause uneven force on the movable cone, thereby aggravating its wear. For example, when large pieces of material enter the crushing chamber, the cone will automatically drop to adapt to the material, while small pieces of material will drop immediately, which not only affects the crushing efficiency, but also changes the direction of the force point, changing the force from multi-directional balance to unidirectional local force.

2、Equipment operation factors

Equipment overload operation: If the feeding amount is too large or the feeding speed is too fast, exceeding the load of the cone crusher, it will increase the burden on the moving cone, and long-term damage to the moving cone will result.

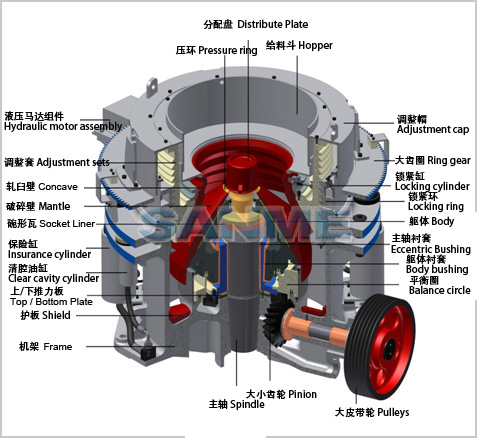

Frequent impact on the moving cone: Non-crushed objects enter the cone crusher, the locking cylinder is damaged, etc., which will cause the moving cone to be impacted frequently. When a certain instantaneous impact load approaches the strength limit of the moving cone, its weak parts will be damaged and produce fine microcracks. Under the long-term action of heavy loads and alternating loads, the microcracks gradually expand, eventually leading to damage to the moving cone.

3、Force situation of moving cone

Unbalanced force: The force borne by the moving cone of the cone crusher during operation is relatively complex, including the inertial force of the cone, the self-weight of the moving cone, the reaction force of the spherical bearing, the reaction force of the eccentric sleeve, etc. If the resultant force of these forces is not zero, the moving cone will be subjected to uneven force, resulting in excessive vibration of the equipment and damage to the moving cone.

Insufficient preload: There is no detection tool for the preload between the moving cone head and the main shaft thread, and the maintenance workers rely on experience in actual work. If the preload does not meet the technical requirements, when the cone crusher is running under load, the cone head will loosen, causing wear of the gear and the moving cone.、

4、Installation and maintenance factors

Poor contact of the support surface: The moving cone of the cone crusher is supported on the spherical bearing of the spherical bearing seat. When the spherical bearing is worn or has quality problems, it will cause the moving cone to move down, and its supporting contact surface cannot be well contacted, which will cause the friction of the moving cone to increase, resulting in serious damage to it.

Liner installation problems: The liner is not leveled and adjusted during installation, the contact surface between the moving cone and the moving cone liner is not cleaned, the locking screws are not tightened in place, and the compression cutting ring is not welded firmly. These problems may cause the liner to loosen or break during the crushing process, thereby affecting the normal operation and life of the moving cone.

In summary, the factors that cause damage to the moving cone of the cone crusher involve materials, equipment operation, force on the moving cone, installation and maintenance, etc. Therefore, when using the cone crusher, the particle size and hardness of the material should be strictly controlled to ensure uniform feeding; avoid overloading the equipment; regularly inspect and maintain the moving cone and its related components; at the same time, strengthen the training and management of operators to improve the operating efficiency and stability of the equipment.